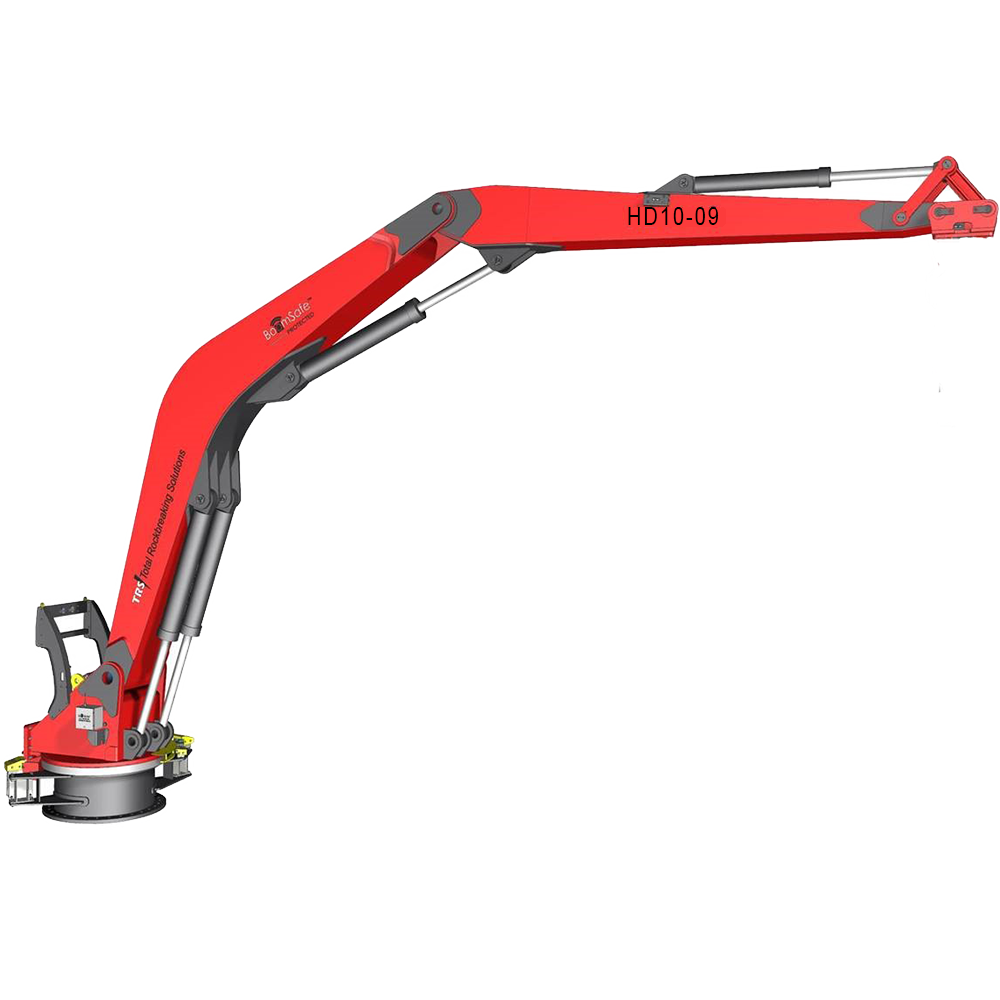

TRS HD10-09 Boom System

Extra-Heavy design engineered for High-Duty applications

Designed for the world’s toughest and most arduous mining applications, the TRS ‘High-Duty’ HD10-09 rockbreaker boom system addresses the increasing demands of large-scale iron ore operations and other high demand mining applications.

The TRS HD10-09 boom system is an extra-heavy, medium reach boom featuring a 1.8m diameter fixed pedestal base.

The TRS HD10-09 boom system is ideal for ROM and Primary Crusher applications and features line-of-sight local radio controls with TRS BoomSafe® protection and automation fitted as standard.

Developed to improve reliability and availability

Representing the first real development in pedestal mounted rockbreakers in over a decade, our engineering team have used the latest 3D modelling and FEA tools to develop a range of HD or ‘High-Duty’ boom systems aimed specifically at improving reliability and availability.

With optional mechanical slew stops and safety rated sensors, slew is achieved through a purpose-built, dual hydraulic drive arrangement incorporating both motion control and anti-cavitation protection.

A premium quality, dual row ball bearing with a safely shielded internal gear provides full 360-degree rotation capability, subject to the connecting hose support design (ask us about our ‘Zero-Tension’ hose support).

Collision avoidance, automated movements and remote operation

Designed for simple operation and to increase productivity and reduce downtime, the TRS BoomSafe® boom control system provides reliable collision avoidance and automated movements at full speed, and is easily expandable to provide a true multi-user remote operation from anywhere in the world.

Key Specifications

Product Weight

22,500 kg

Slew Range

360°

Maximum Horizontal Reach

12.6 m (hammer extended)

Standard features

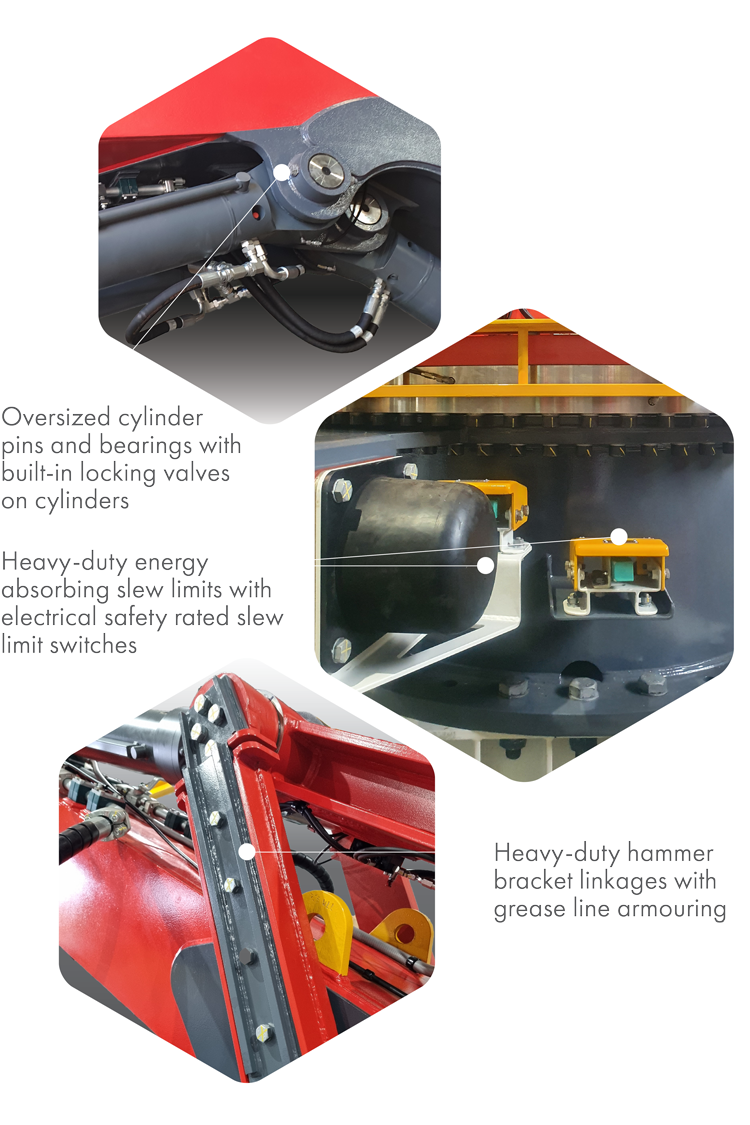

- High flow control valves and large diameter pipes and hoses for higher speed of operation i.e. reduced PARK and DEPLOY times.

- Compatible with large and extra-large hydraulic hammers to achieve maximum rockbreaking productivity.

- 360-degree slew with a large diameter dual row ball bearing incorporating a protected internal gear and dual heavy-duty purpose-built hydraulic drives.

- Heavy-duty linkage assembly on head bracket for maximum hammer tilt and raking force for quicker grizzly or crusher clearing.

- Heavy-duty cylinders with friction welded cylinder rod ends.

- Load holding over-centre valves on ALL cylinders.

- Hard chromed cylinder and pivot pins.

- Complete automatic lubrication for boom system pivot bushes and all bearings.

- TRS BoomSafe® boom control system fitted as standard.

Optional features

- BoomSafe® Remote Operation with true multi-user capability.

- Heavy-duty energy absorbing mechanical stops for slew limits.

- Primary and secondary fail-safe LEFT and RIGHT slew sensors.

- TRS ‘Zero-Tension’ interconnecting hose support.

- TRS ‘Clean–Fill’ lubrication cabinet with option of grease drum or remote fill stations.

- Hammer change and tool change frames for safe and fast maintenance.

- TRS ‘Single-Isolation’ hammer change system for minimum downtime.

Typical applications

- ROM Bin Static Grizzly duty

- Gyratory Crusher duty

- Jaw Crusher duty

Specifications

Weight | 22,500 kg (with hammer) |

Maximum Vertical Reach (m) * | 8.5 m down |

Minimum Horizontal Reach (m) * | 9.8 m (hammer vertical) 12.6 m (hammer extended) |

Slew range | 360 ° |

Rockbreaker tilt angle | 130 ° range |

Rockbreakers (Rammer) | 3288E, 4099E ** |

Recommended Hydraulic Power Units | 90kW (std) | 110kW (Hi-Flo) |

* Based on 3288E Rockbreaker with Standard Tool.

**For longer reach applications the TRS XD Series booms are available with extra large rockbreakers

Specifications are subject to change without notice.