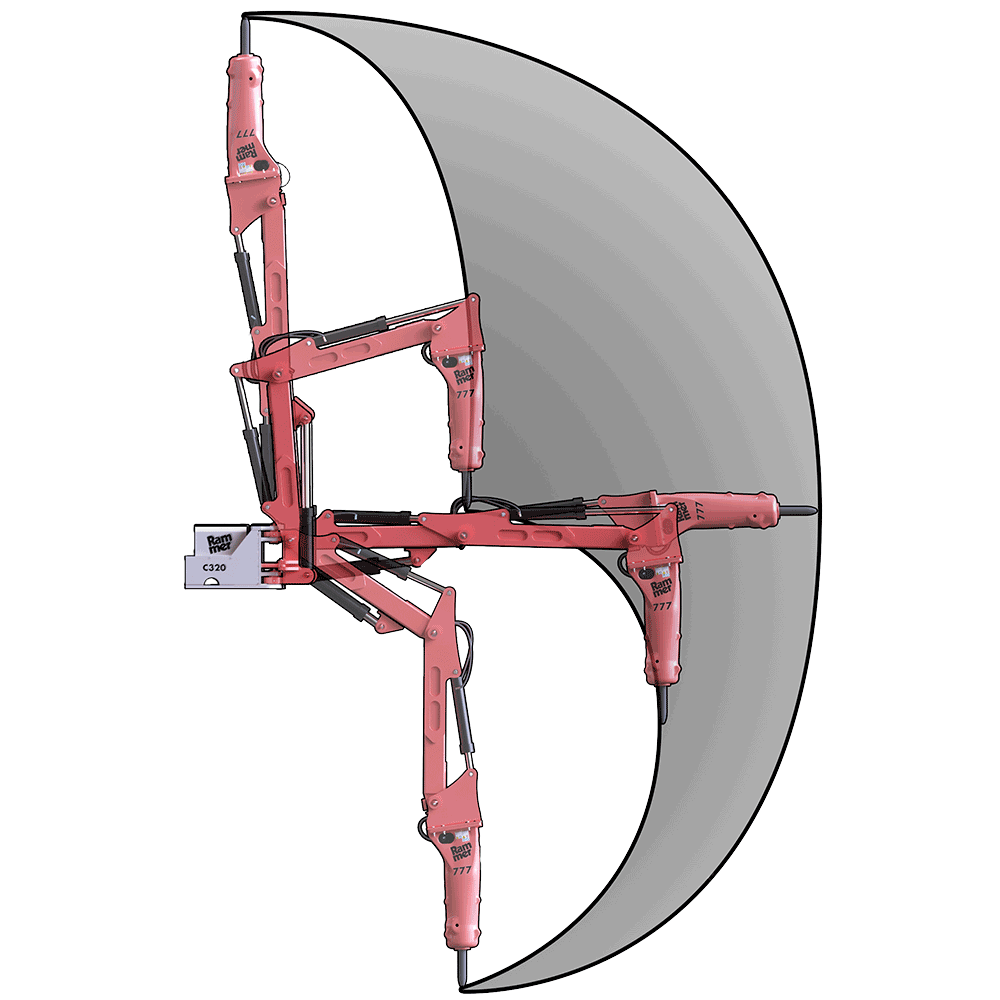

Rammer Boom to accommodate any application

Rammer Boom Systems have been an integral part of Australian crushing circuits for more than 40 years. Manufactured on a global scale for a global market, Rammer has 28 models from 1 tonne up to 18 tonne heavy duty models. With reaches from 1 metre up to 17 metres there is a boom to suit all types of mining and quarrying applications – from smaller stationary crushing plants and mobile crushers to gyratory crushers and ROM bins.

We will help you take advantage of the extensive Rammer product range by selecting the right boom and rockbreaker for the job. By packaging this with the correct controls and power pack to match your requirements, and working with you we can optimise the installation to ensure reliable operation and maximum productivity and serviceability.

Productivity

Rammer Booms maintain optimum crusher throughput and enable the optimal positioning of a breaker within crushers feed, allowing blockages and bridging of rock to be broken and cleared safely, reducing breaking times and maximising productivity.

Maintenance and Spare parts

Factory-approved maintenance and warranty services to maintain your boom in peak condition at all times and the standard range of spare parts and tools are readily available globally.

Safe turn-key package

A complete safe turn-key packages available comprising rockbreaker, boom system, power pack and full electrification of the system that are customized to meet specific needs and ensure optimum safety, reliability and durability.

4 things to consider before buying a boom system

Pedestal mounted hydraulic boom systems are typically installed above crusher inlets or ROM hoppers and grizzly screens to minimise downtime and avoid damage caused by oversize product blocking chutes or crusher inlets.

To maximise the return on this investment and ensure optimum performance, it is important to consider the following before purchasing a new rock breaker boom system:

- A correctly sized hydraulic rockbreaker

- The Boom size and reach

- Position, elevation and working slew angle of the boom

- Safety systems, automation, remote operation and spare parts

Download the information sheet for details.

Rammer Boom Systems

Increase safety with smart boom technology

Increasingly, mine operators are turning to technology and remote operation to reduce the exposure to risk for operators and nearby personnel.

Developed specifically for hydraulic boom systems BoomSafe® combines automated movement sequences, collision prevention and it allows remote operation of your boom systems via a plant network at any location in the world via a laptop or PC.

BoomSafe® is the most advanced remote operator controlled, collision prevention and automated movement system on the market and you can have it factory fitted on new Boom Systems or retro-fitted to your existing Boom. READ MORE.

Enquire Now